SonoAnalyzer Pro version 2.3.2

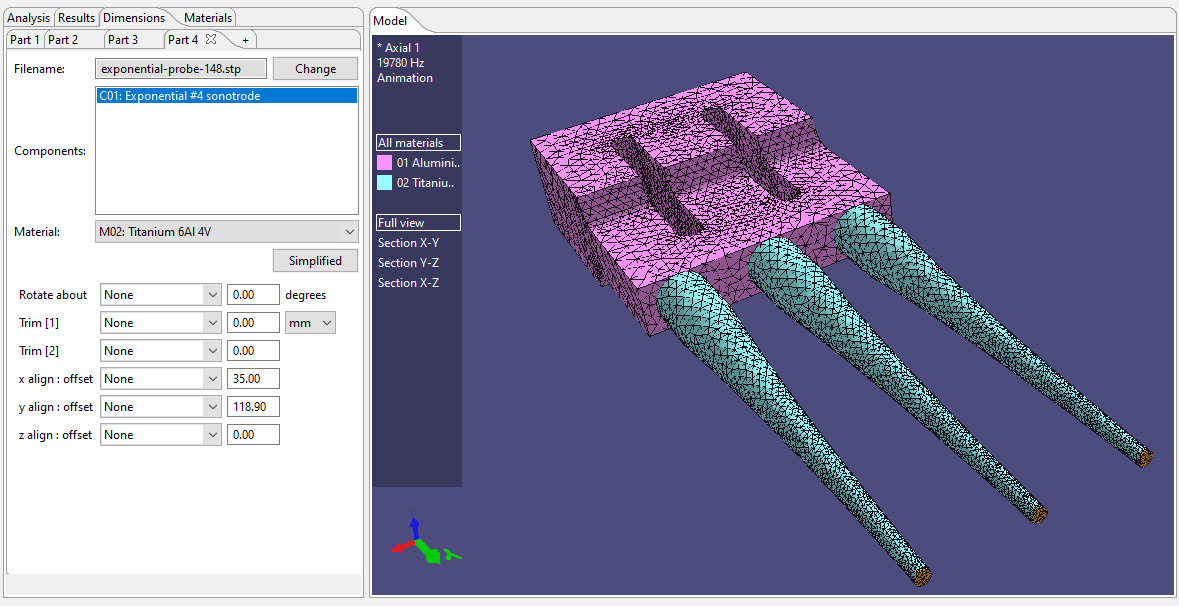

Announcing the release of a new SonoAnalyzer, version 2.3.2, in Pro, OE and Free editions. This is the fully-functional release of the new STEP multi-element model, which allows for a combination of multiple STEP files containing geometry, or a single STEP file containing the geometry for multiple components, or both. No matter how the component geometry is defined, different materials can be selected for each individual component.

Announcing the release of a new SonoAnalyzer, version 2.3.2, in Pro, OE and Free editions. This is the fully-functional release of the new STEP multi-element model, which allows for a combination of multiple STEP files containing geometry, or a single STEP file containing the geometry for multiple components, or both. No matter how the component geometry is defined, different materials can be selected for each individual component.

As on the earlier beta version a simple demo model is included in the package, which will load when the model type is selected. This is a concept for an ultrasonic scraper with a common utility-knife blade clamped into an aluminium stepped sonotrode using two small screws. All four components are defined in a single STEP file and entered as three geometry sub-tabs in SonoAnalyzer (one tab for each material - the two screws are selected together on the third tab). Defining all four components in the same STEP file makes it simple to establish their relative locations.

As on the earlier beta version a simple demo model is included in the package, which will load when the model type is selected. This is a concept for an ultrasonic scraper with a common utility-knife blade clamped into an aluminium stepped sonotrode using two small screws. All four components are defined in a single STEP file and entered as three geometry sub-tabs in SonoAnalyzer (one tab for each material - the two screws are selected together on the third tab). Defining all four components in the same STEP file makes it simple to establish their relative locations.

Where multiple components are defined in separate files, they will not usually be correctly positioned. In this case new "Advanced" options allow for rotation and alignment of each individual part. This can also be used to add multiple copies of a component in different positions. Furthermore components need not necessarily be additive; if the special "Subtract" material type is selected then the component will be treated as a hole or slot in the other (solid) components. Some further changes in the SonoAnalyzer graphics window for this new model type only. On the geometry view (after redraw, before analysis) and on the animation view (after analysis) the area on the left of the graphics window, normally used for a key on contour plots, now shows a list of materials used in the model. Click on any one of the material labels to show only that material, or click on the "All materials" label to return to the standard view of all components. This feature works alongside the existing sectional views (double-click on the graphics window to toggle through available sections) but the sectional view options are now also shown in the key on the left side of the graphics window.

Some further changes in the SonoAnalyzer graphics window for this new model type only. On the geometry view (after redraw, before analysis) and on the animation view (after analysis) the area on the left of the graphics window, normally used for a key on contour plots, now shows a list of materials used in the model. Click on any one of the material labels to show only that material, or click on the "All materials" label to return to the standard view of all components. This feature works alongside the existing sectional views (double-click on the graphics window to toggle through available sections) but the sectional view options are now also shown in the key on the left side of the graphics window.

Some deprecated features are not available in this model / version, notably external graphics using the CalculiX cgx program, .stl file import and the use of Netgen for mesh generation. If any users have a specific need for these please contact me to discuss your options.

To support the new analysis, new pro analysis servers are also required (designated v3, replacing the earlier v2 servers). For cloud-server users there is an option within SonoAnalyzer to request an upgrade - just click the OK button on the warning popup that appears when the new model type is selected with a v2 analysis server. For users of locally-installed analysis servers a new Windows binary is available to download from the Pro support packages page (FEAServer setup.exe version 3).

As always, if you find any issues please let me know. More details follow.

UI updates:

As first seen on version 2.30 beta, the new model features the same building blocks as previous versions but in a different arrangement, giving increased flexibility required for multiple geometries and multiple materials. The four top-level input tabs will be familiar to users of older models: Analysis, Results, Dimensions, Materials. But under the Materials tab there may be up to 10 sub-tabs where user can define a "pallette" of all materials to be used in the model. Then under the Dimensions tab more "Part" sub-tabs define the geometry to be analyzed and a selection box for the material to be used. In addition to a material selection the special option "Subtract" is also available. As the name implies this flags the selected component geometry to be cut from the remaining parts. This could be used for example to cut a special profile into a simple shape.

The graphics window now allows selection of a single material or all materials in the new analysis type, as described above.

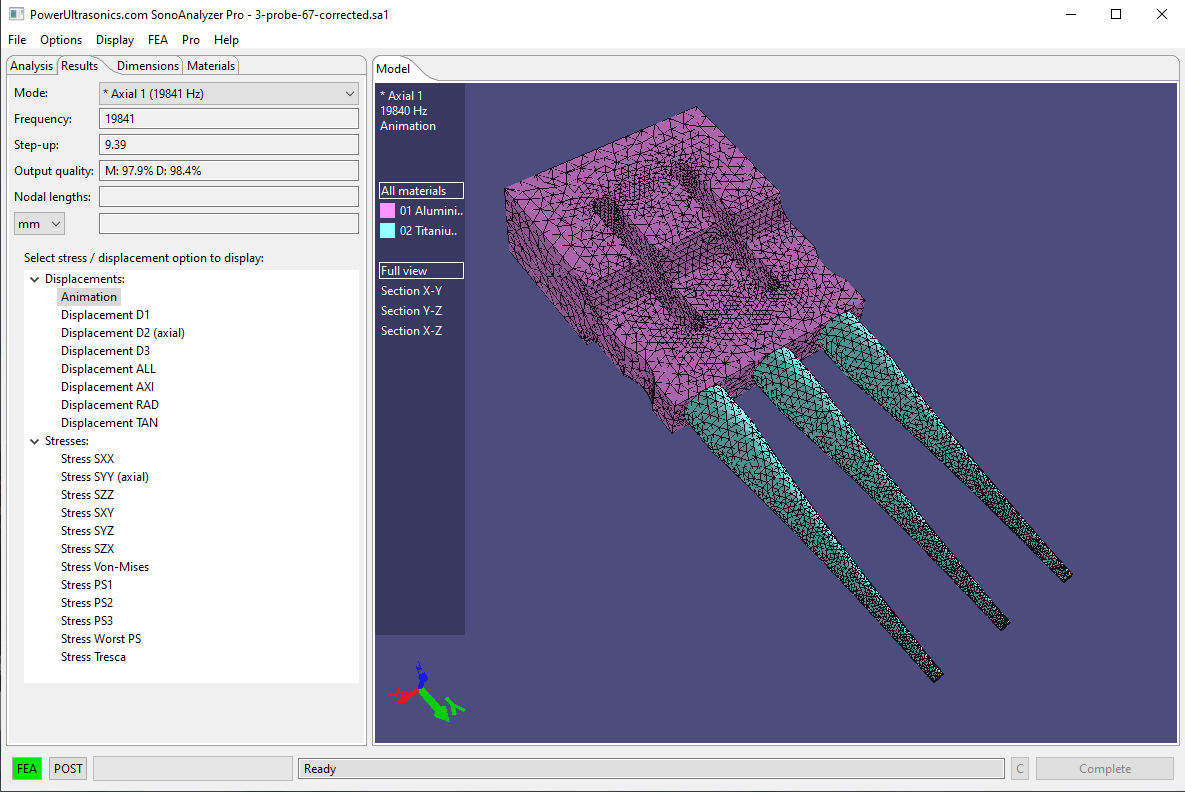

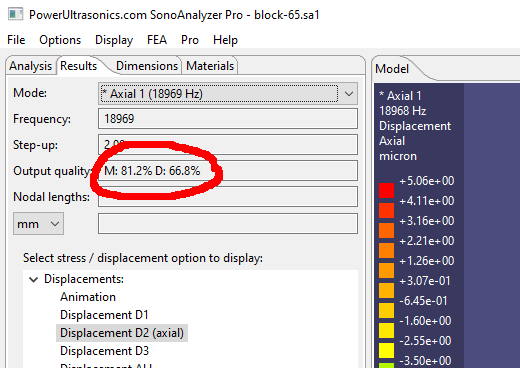

A new "Output quality" measure now appears in the results tab for all recent Pro models. This shows percentage values marked "M" and "D" (eg. M: 95% D: 98%). these relate to the motion on the output surface of the sonotrode (generally the area coloured orange on the geometry view). The M value represents the variation in magnitude of the axial component while the D value indicates the variation in direction of the motion. These figures of merit hold little significance in themselves but do serve to accurately compare different designs.

A new "Output quality" measure now appears in the results tab for all recent Pro models. This shows percentage values marked "M" and "D" (eg. M: 95% D: 98%). these relate to the motion on the output surface of the sonotrode (generally the area coloured orange on the geometry view). The M value represents the variation in magnitude of the axial component while the D value indicates the variation in direction of the motion. These figures of merit hold little significance in themselves but do serve to accurately compare different designs.

An article will be published shortly describing the use of this feature, along with the advanced positioning options described below..

STEP multi-element usage:

First create geometry in your preferred CAD program as a number of separate components and export this model in STEP format. The use of meaningful names for each component is highly recommended.

To start a new analysis in SonoAnalyzer, first click on the "Materials" tab and in the sub-tabs labelled M01, M02 etc, select all the materials you want to use for the analysis. As usual preset materials are available or custom / user defined materials can be set up by defining the elastic properties. Then go to the "Dimensions" tab and remove all parts other than Part 1 by clicking the X in the tab title. In the "Part 1" tab, click the "Change" button and select the STEP file you exported from CAD. After a new file is selected for analysis the message "Please wait for STEP file checks" will be displayed briefly, while SonoAnalyzer evaluates the components contained in the file, reading their names and extents (the range of x,y,z values covered by the geometry) and presenting them for selection in the "Component" multi-select list. Select one or more components and in the "Material" selection box, choose a suitable material. Next click the "+" tab to the right of the other part(s). The new tab is automatically populated with the same STEP file and components list, so another component can be selected and another material. And this continues until all components have been selected. Now click "Redraw" (or wait for timeout) and SonoAnalyzer will proceed to create a multi-material mesh, displayed on screen in different colours for each material. Having checked that the geometry is all as expected, click the "Analyze" button to run the FEA analysis (as for previous Pro models).

If all geometry is not defined in the one STEP file then another file can be used in the same way, using the "Change" buton and selecting the new file. Note that the components in the two files must be correctly positioned relative to each other. If this is not the case then each component can be rotated as required and automatically aligned with the others.

Multiple STEP files vs multiple components in a single STEP file:

In the earlier STEP-import model type, if the STEP file contained more than one component, SonoAnalzyer would load and analyze only the first component, ignoring all others. With the same file imported into the new model type, SonoAnalzyer will now process the file, detect the multiple components and present them to the user for selection in different materials. Defining components in this way is highly recommended since the relative location of each component is pre-defined by the user. Alternatively further STEP files can be loaded and components within those files will be presented for the user to select.

Advanced positioning options:

Additional options for aligning and positioning components relative to each other are now available via the "Advanced" button on the part tab. Specifying a rotation axis and angle (typically 90 degrees) are used where the components were designed on different axes, and alignment brings the centre, minimum or maximum values into line with the adjacent component. Specifying an offset along with alignment can also be used to add multiple copies of a component in different positions. Furthermore components need not necessarily be additive; if the special "Subtract" material type is selected then the component will be treated as a hole or slot in the other (solid) components. So for example in the design of a slotted block sonotrode a single slot can be included as a component and multiple slots created with easy adjustment of their positions.

Contacts, gaps, overlaps:

Where two components have a contacting surface the mesh created will link them across that surface. This can be imagined as gluing them together using an infinitely strong adhesive. Where there is a gap between nearby surfaces (I suggest at least 0.05mm) the surfaces will not be connected and will be free to move independently. In the animated results display (which greatly exaggerates the motion) such surfaces may well overlap during part of the cycle but this doesn't represent reality - it's just a display effect. Where different components really do have overlapping geometry such overlaps will be eliminated before meshing, leaving the components in contact.

Where an overlap is found the component defined later will maintain its shape while the one defined earlier will have the overlapping section cut out.This is demonstrated in the STEP file "overlap-cylinders.step", available from the downloads page. This features a solid inner cylinder (longer, with a smaller diameter) and an outer cylinder (shorter, with a larger diameter). If the outer cylinder is defined first, as Part 1, and the inner cylinder as Part 2 then during processing the inner cylinder will be left intact while the outer has a hole cut through it. Conversely if the inner cylinder is defined first, as Part 1, and the outer as Part 2 then the outer will be intact and the inner will be cut into two parts.

Trim and tune:

Another option included in the "Advanced" section is to apply one or two trim actions. These can reduce the size of a component in a specified direction or limit the inside or outside radius to a specified value. In all cases these options only act to remove material from a component geometry supplied by the user. This offers a convenient way to model the normal physical process of manufacturing a sonotrode oversize and then machining it down to achieve a desired frequency. The process can also be automated using the "Auto tune" option on the Analysis tab. Note that after this is selected you will need to go to the Dimensions tab, select the component you want to adjust and select the appropriate item from the "Tune on" option selector. Most commonly this will be one of the two trims, but tuning on one of the offset values is also possible as the offsets can overlap two components so one is reduced in size (as described above).

Export finished geometry:

Where overlaps have been found or the trim / tune options have been used the geometry analyzed is different to that in the original imported STEP file(s). So after completing the analysis the menu option "File -> Export -> 3D model (STEP)" will produce a combined STEP file containing all the modified geometry. This STEP file can be viewed in your CAD system or re-imported into SonoAnalyzer where it can form the basis of a new analysis with all advanced options disabled, perhaps as a start point for further optimization.

Smooth midside nodes?

The "Smooth midside nodes" option appears on the earlier STEP / STL import model but is not shown in the new model type because second-order geometry (correctly placing mid-side nodes on curves) is now generated directly in Gmsh. however for some geometries, particularly where there may be small-radius curves, this can cause a "non-positive Jacobean" error on Finite Element analysis. In many cases this can be overcome by choosing a finer mesh but for cases where that is impractical or ineffective a new FEA option has been added: "NPJ geometry compensation". Options include:

- "None" - the default with mid-side nodes located correctly on the curves.

- "Refine by splitting" - This splits the elements at the midside nodes, creating a new mesh that looks much finer than the standard one. However the elements used here are 4-noded tetrahedra with no midisde nodes in place of the usual 10-noded tetrahedra. Overall the total number of nodes and the time to complete the analysis will be similar for both types.

- "Second order linear" - This uses the same elements as the default option but the midside nodes are not placed on the curved geometry; instead they are placed exactly half-way between the corner nodes. So with this option the surface looks a little rougher but is still a fairly close approximation to the true geometry. This is similar to the earlier STEP / STL import analysis with the "smooth midside nodes" option unselected. Again the total number of nodes and time to complete the analysis will be similar to the default.

For any given mesh fineness the best accuracy will be achieved by using the default option "None". Users are advised to consider the others only when analysis produces non-positive Jacobean errors (which will trigger a prompt from SonoAnalyzer). Comparing the other options, refine by splitting produces a mesh that more closely follows the curves of the geometry but the elements tend to be sitffer than they should be, generally leading to an overestimate of the resonant frequencies. The elements produced by the second order linear option do not suffer this problem but they deviate from the true curved geometry a little more, which can lead to underestimating the frequencies (if the reduced element size affects mainly the high-stress areas, reducing overall stiffness) or overestimating them (if the reduced element size affects the low-stress areas more, reducing the mass there).

New analysis servers:

The new analysis includes a series of geomety processing operations to identify and manipulate the components defined in the user's STEP files. This work requires a newer version of FreeCAD than previous analysis servers included. The meshing also benefits from a newer gmsh version. New analysis server packages, designated v3, are available for the online "cloud" servers provisioned to all current Pro users or as a Windows binary for download. In the interest of simplicity some functionailty associated with deprecated SonoAnalyzer Pro features has not been included in these packages.

CalculiX cgx is no longer a modified version allowing remote-control through SonoAnalyzer; instead a standard version is used (version 2.17 to 2.21).

Cygwin/X (used for interactive graphics in CalculiX cgx) is no longer included in the Windows binary.

TigerVNC server (used for viewing CalculiX cgx graphics on a remote server) is no longer included in the cloud servers.

Netgen is not included in any v3 analysis servers. Gmsh was already the preferred option for STEP imports; it is now a requirement.

So when connected to a v3 analysis server all operations under the FEA menu (which rely on connecting to cgx) will no longer work: Mode animation, Displacement plot, Axial displ plot, Stress plot, Capture current. These functions were deprecated already as the standard SonoAnalyzer graphics have provided equal or greater functionality since version 1.7.1. From version 2.3.0 onwards all FEA menu options are disabled when connected to a v3 server.

How it works:

The new model type uses geometry processing provided by FreeCAD, meshing by Gmsh and FEA analysis by CalculiX ccx, all open-source software provided in the FreeCAD distribution package. The CalculiX pre- and post-processor cgx is used only for the "linear second order" meshing option.

Information for new purchasers (Pro):

New purchases from now will be provisioned with version 2.3.2 software and version 3 analysis server as standard. For those running earlier 2.x versions the corresponding upgrade to a version 3 analysis server is available on request. Version 1 is no longer offered or supported.

Running a version 3 Pro analysis server is a requirement to us the new model type. For other analyses and the previous version 2.2.0, one that includes the Gmsh mesher is strongly recommended. All current cloud servers do provide this. Users wishing to run their own standalone servers should install the latest version of the FEAServer setup.exe file, currently 2.0.2, from the downloads page, or see full details here.

For information on all available products please see the purchase page.

Information for new purchasers (OE):

New purchases will be provisioned with version 2.3.2 software. Please note that these new STEP-import models are not available on SonoAnalyzer OE, only on SonoAnalyzer Pro, but SonoAnalyzer OE can be used to view results files generated by SonoAnalyzer Pro version 2.3.2.

For information on all available products please see the purchase page.

Information for current license holders (Pro and OE):

Updates are included with your original purchase for one year. Within that time the new download can be found in your user account under the "Files" tab.